(日本語) 第129回塑性加工学講座で講義を行います

- 23. Jan, 2013

- Event Information

Sorry, this entry is only available in 日本語.

Related Products

-

-

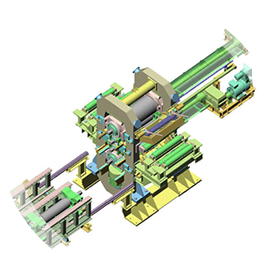

Plate Leveler

The SuPerLeveler™ was developed by JP Steel Plantech in 1998 as equipment to improve the flatness of steel plates (6 mm to 50 mm thick) produced in plate mills. Warping generated in the leveler (surface preparation materials to increase horizontal precision) during correction is also completely corrected through infinity control of rigidity. This has made it possible to flatten TMCP steel plates, hardened steel plates, and other steel plates that require straightening reaction, and which did not become stable using conventional levelers.

-

-

Temper /

Skin Pass MillsThe device uses skin pass rolling to improve the mechanical properties and surface texture, and improve flatness, in order to form materials such as hot-rolled steel sheets, cold-rolled steel sheets, stainless steel plates, and aluminum plates into final products. Since it conducted tests with its own test equipment in 1965, Steel Plantech has continued to develop theories and deliver actual devices. As a result, the company has delivered 63 skin pass mills worldwide up to this point in time.

-

-

Tension Leveler

Tension levelers level and improve the flatness of materials such as hot rolled steel, cold rolled steel, stainless steel, aluminum, copper and specialized materials, and finish them into a final product. The range of the materials that can be used for leveling are those with a thickness of between 0.05mm-8.0mm, a width of between 300m-2,300mm and a yield strength of between 50MPa-1,500MPa. Tests of various materials using original testing equipment have been carried out on Steel Plantech’s tension levelers since 1970. Theories have been constructed, tested, and supply of tension levelers made, with this repeated many times over the years. 194 sets have been supplied around the world, practically making Steel Plantech a specialist in tension levelers.