Solutions

Production Cost Reduction

-

30 %

Blending ratio of non- or slightly-caking coal for coke oven material

-

95 %

Annual operating ratio

-

185 kWh/t-coke

Electric power generation

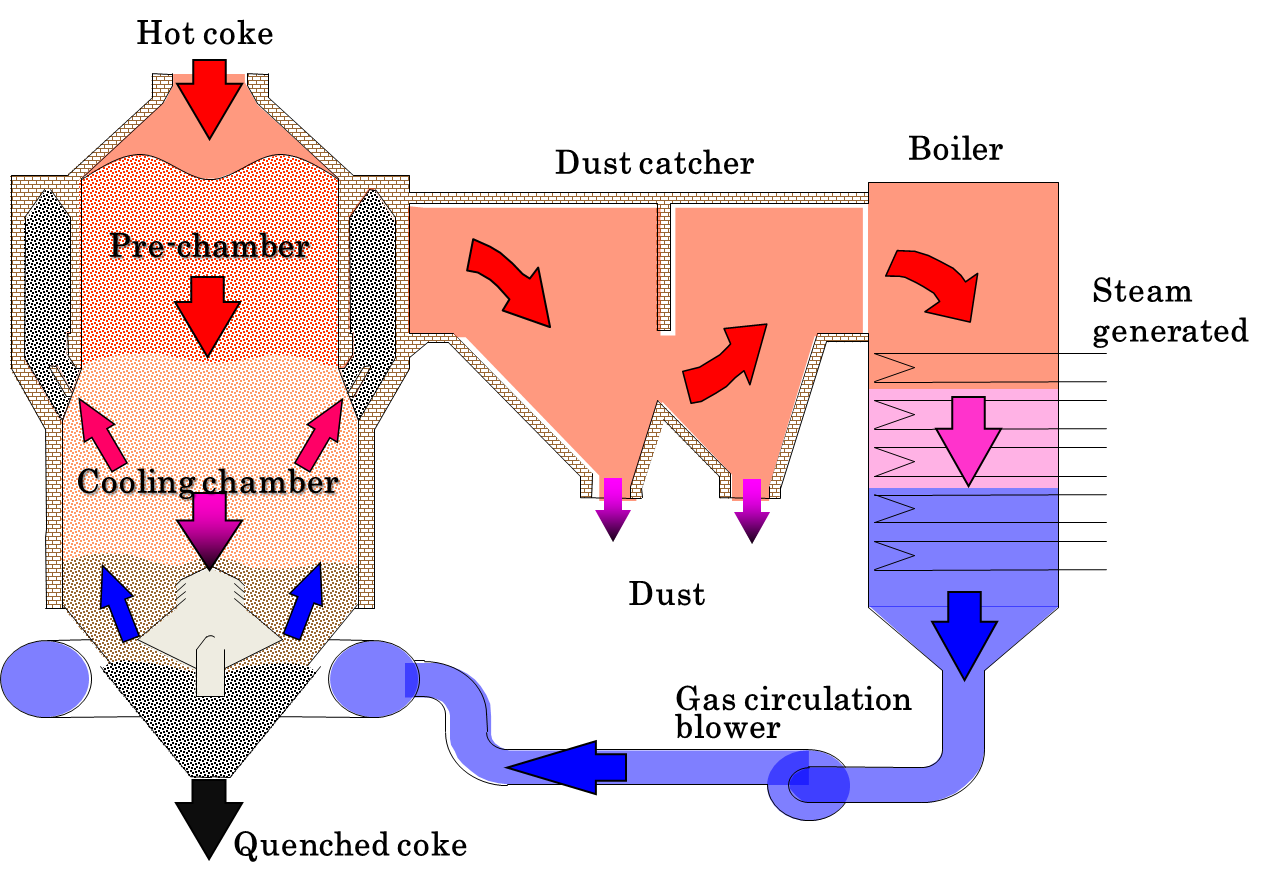

Feature of CDQ process are follows.

- CDQ (Coke Dry Quenching) is a gradual coke quenching system, and improves coke strength and coke size distribution. Consequently, while the blending ratio of inexpensive non- or slightly-caking coal for coke oven material is only approx. 15% in case of CWQ (Coke Wet Quenching) system, it can be increased up to approx. 30% by CDQ, resulting in a cost reduction with raw materials for coke oven.

- The CDQ coke has lower moisture content (0.1 to 0.3%) than CWQ coke (2 to 5 %), and the Coke ratio of Blast furnace can be reduced.

- Combustible component and coke dust in circulating gas are burned by blowing air into the gas, and so the temperature of the circulating gas can be raised. Thus, steam generated by the waste heat boiler can be increased.

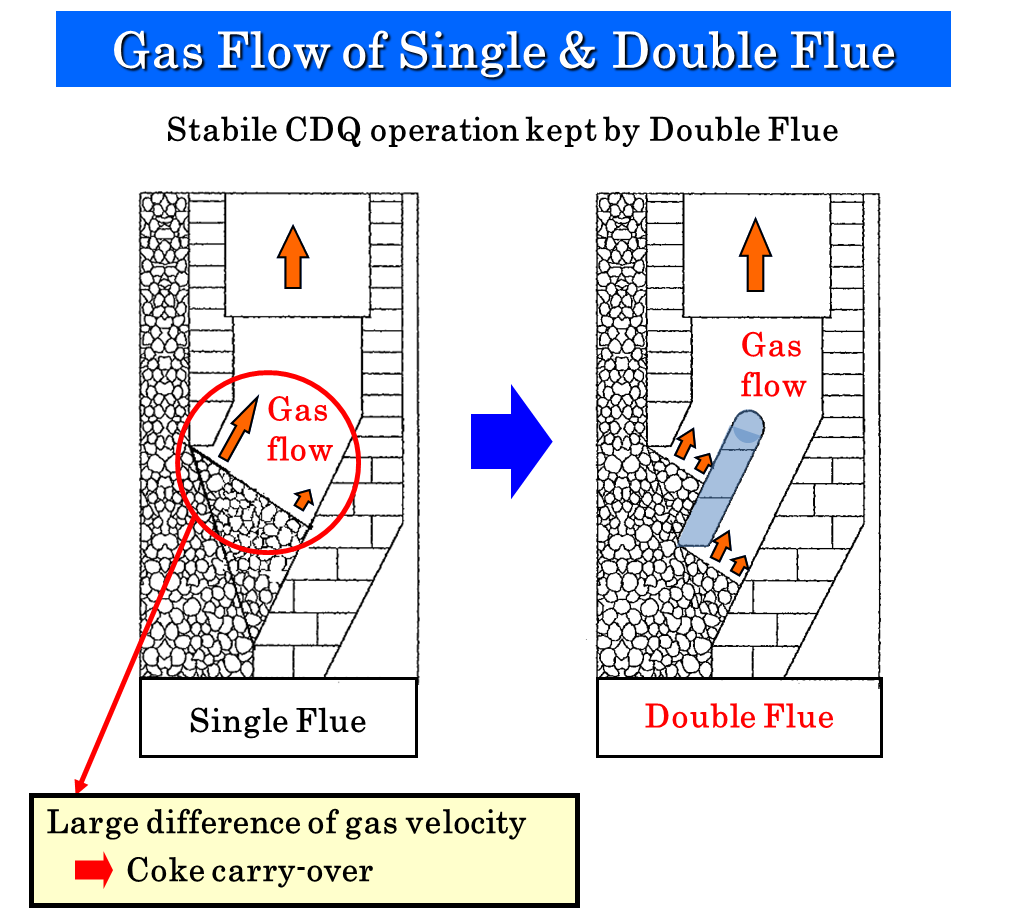

- A high annual operating ratio of 95% can be achieved by combining the Double Flue technology, appropriate refractories and highly reliable equipments.

- Steam generation of 500-700 kg/t-coke and power generation of 140-185 kWh/t-coke can be obtained, according to CDQ operation and steam conditions.

- Such excellent features realize the payback period of initial investment within three to five years.

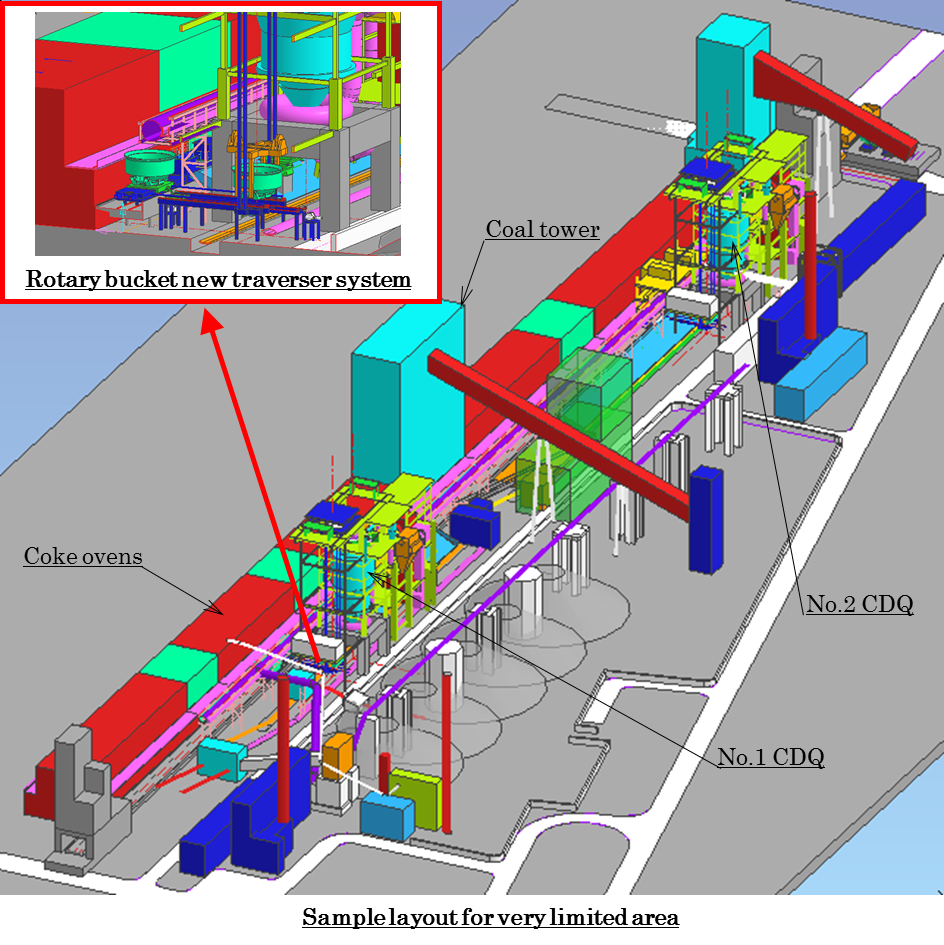

Customization

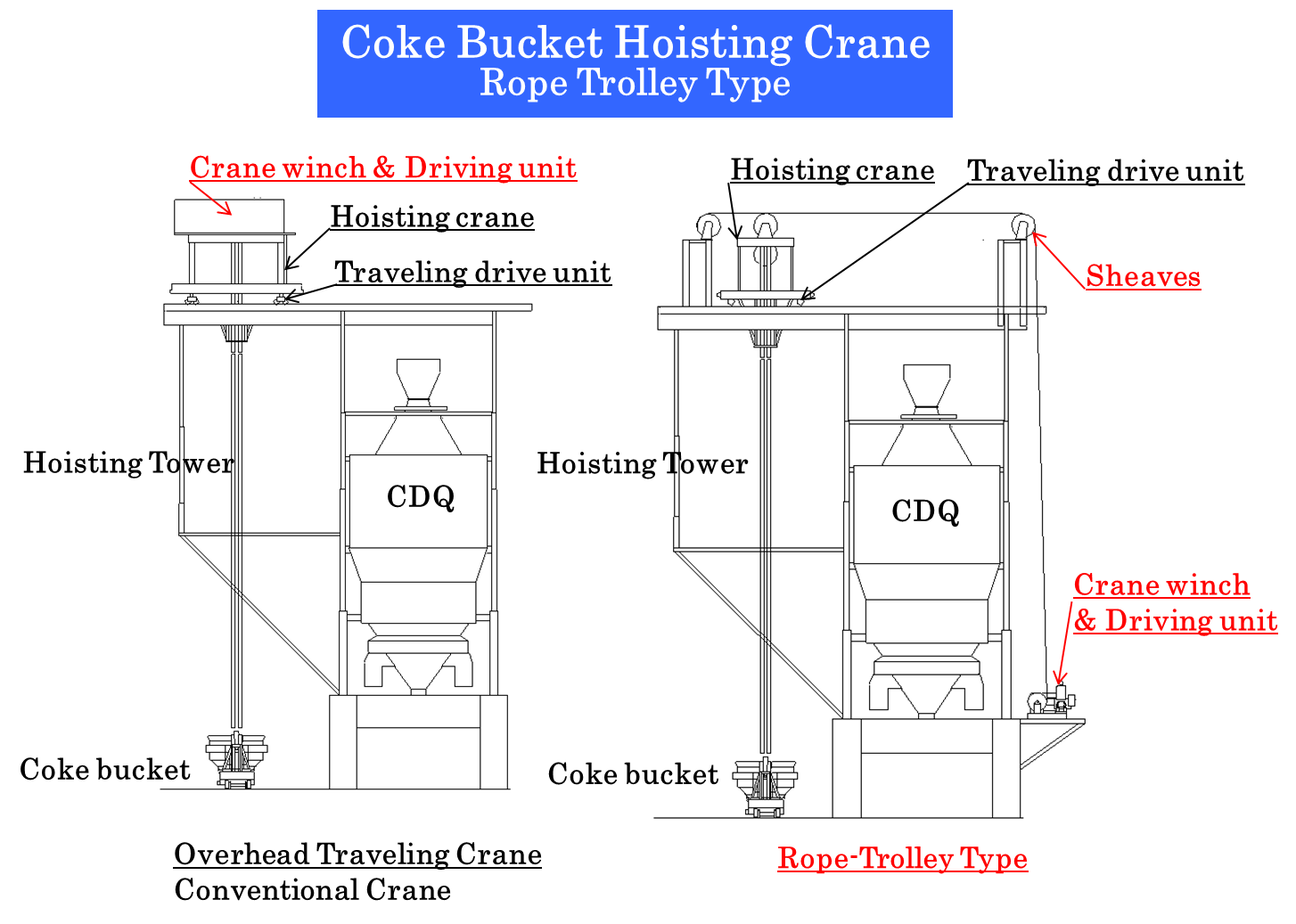

Steel Plantech has developed “New coke handling system (*1)” and “Rotary bucket new traverser system (*1)”. Such technologies enable the layout flexibility of CDQ. Our large CDQ can be introduced even in a narrow space where it is difficult to install the conventional CDQ system. Our design meets customer’s requirement.

(*1:Patented)

Steel Plantech has technologies and experience to offer and resolve the following problems which customers may face:

- Have given up CDQ installation because of the narrow space around coke oven batteries;

- Want to increase the CDQ operation ratio;

- Want to secure stable CDQ operation;

- Want to extend the life of refractories;

- Want to resolve the trouble of Collision wall drop off in the Dust catcher; and

- Want to extend the life of equipment such as waste heat boilers and gas circulation system.

Environmental Friendliness

- CDQ is one of the excellent countermeasure to global warming. Recovered heat by CDQ is used to generate steam or electric power, which leads to a reduction of fossil fuel usage at power plant. Thus, you can reduce CO2 emissions in total.

- In CDQ, red hot coke is quenched in a closed cooling gas circulation, CDQ remarkably reduces the dust to be released into the atmosphere as compared with the CWQ.

Product Quality Enhancement

CDQ is a gradual coke quenching system and can improve the coke strength, as the raw material for blast furnace. And coke size distribution can be improved in the process of descending coke packed bed.

These characteristics are useful for stable operation of a blast furnace, in order to secure good gas and solid reaction by keeping permeability in a blast furnace.