Received the First Order for S-ROBOT, a Temperature Measuring Sampling Robot of the Smart Products “S-Series” Utilizing AI and IoT Technologies, from KYOEI STEEL LTD.

- 24. Sep, 2019

- Press Release

JP Steel Plantech Co., a steelmaking plant engineering manufacturer (President: Nobuyuki Nada; head office: Yokohama-shi, Kanagawa), has received an order for a temperature measuring sampling robot, S-ROBOT, which is a new product in the “S-Series,” from KYOEI STEEL LTD. for its Hirakata Division. It is scheduled to start operation in August 2020.

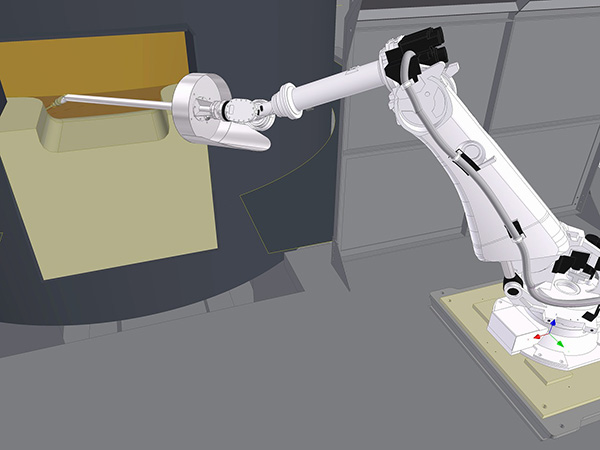

S-Series is the general name of the smart products that we have developed with the concept of using AI and IoT technologies to increase the added value of hardware and services of existing products. S-ROBOT is a temperature measuring sampling robot for electric furnaces that can perform the sampling work that has been done manually so far. The probe, which is used for each operation, can be replaced automatically. This helps to promote labor saving and improve safety at the same time. All of the parts for the product to be delivered will be made in Japan, which gives us the advantage of being able to centrally control all maintenance services.

We received this order because KYOEI STEEL is promoting a fully automated furnace front work as one of its measures for work-style reform. We will continue to develop items mainly in the fields of electric furnaces, continuous casting, and steel bar rolling, to achieve factory safety and save labor using robots, improve operation and product quality by using images, AI, and big-data analyses, and provide operation support service based on process analysis. We aim to make systems smarter, such as achieving one-man operation, central integration of operation rooms, which used to be installed at each plant, and remote operation.

Visual explanation: Illustration of S-ROBOT collecting samples with its arm. The probe is automatically replaced.

Related Products

-

-

Electric Arc Furnace

Steel Plantech’s electric furnaces for steelmaking are core products succeeded from JFE Engineering (formerly NKK).

Its abundant experience as a steelmaker (or in other words, a user) in addition to technical know-how gleaned from experience in the design and engineering of electric furnaces for steelmaking, accumulated since 1968, enabled the provision not only of electric arc furnaces and auxiliary equipment, but also a wide range of metallurgical and operational technology.

-

-

Ecological and Economical Arc Furnace (ECOARC™)

ECOARC™, the ecological and economical arc furnace developed independently by Steel Plantech, is filled with innovative technology. It comes with advanced scrap preheating technology that eliminates the white smoke and foul odors generated when melting scrap metal, and addresses environmental requirements of the future. Furthermore, it is equipped with melting technology that achieves higher productivity than conventional electric arc furnaces.