All-in-one Acid Regeneration Plant SARA Now Available in Japan – Bringing the Latest European Technology to Japan

- 10. Nov, 2020

- Press Release

- Product Information

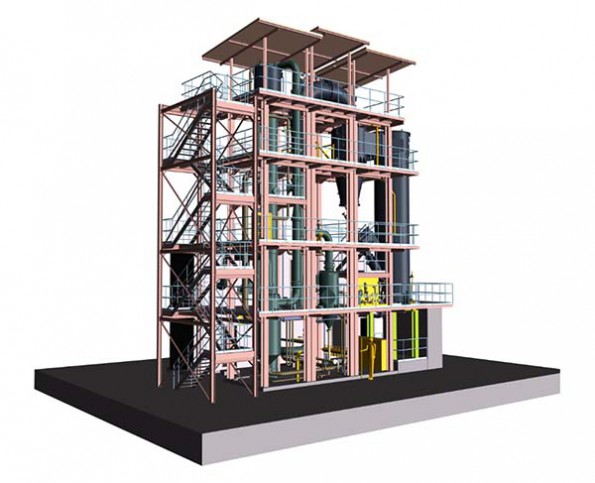

3D model of SARA® , which is much more compact compared with the conventional model. ©2020 John Cockerill

JP Steel Plantech Co., a steelmaking plant engineering manufacturer (President: Nobuyuki Nada: head office: Yokohama-shi, Kanagawa), has started selling a compact acid regeneration plant (ARP) SARA® (small acid regeneration assembly) developed by John Cockerill UVK of the John Cockerill (hereafter referred to as JC) Group, a Belgian general engineering manufacturer with whom Steel Plantech has concluded a business agreement.

With a history of over 150 years, UVK provides high-quality pickling ARPs widely all over the world. It delivered about 40 units of ARP in the 2000s alone. However, the design and installation of conventional models were customized for each customer, so it was difficult for customers with medium- or small-sized pickling processes to make investments when considering the return on investment.

This newly developed SARA® employs UVK’s latest ARP technology and it is more compact, so it can be used for medium- or small-sized pickling processes. In addition, it features an all-in-one configuration with a module or a unit that includes the control equipment, which helps shorten the construction period and simplify installation. The product lineup encourages investment, with two types (500-800 L/h and 800-1,300 L/h) on offer to meet various processing capacities that are in high demand. UVK has recently received an order for the design, manufacturing, and complete supply of a SARA® ARP in Turkey, which is scheduled to complete trial operations in early 2021.

UVK’s ARP can handle two processes, namely fluidized bed roasting and spray roasting. There is a demand for the renewal of large-capacity ARPs, so UVK will continue to design and manufacture facilities according to the customers’ capacity requirements and methods. Moreover, UVK owns the latest pickling technology, so it can update the corresponding ARP facility as soon as a pickling process is updated. Meanwhile, in response to requests for medium- or small-scale ARPs, introducing SARA® can lead to an early return on investment. Similar to conventional ARP facilities, the operation of SARA® can also be monitored in the pickling operation room, based on integrated operation in the control system of the pickling line.

By adding SARA® to our products in addition to JC’s current pickling and ARP facilities, Steel Plantech will be able to supply environmentally friendly and consistent pickling process facilities regardless of throughput volumes. Our business alliance with JC is entering its third year and we will continue to make proposals to meet each customer’s needs from a global perspective.

[Details of SARA®]

SARA® was developed in 2019 for pickling lines with relatively small amounts of waste acid generation and sales was started in the same year.

- Simplified installation and a short manufacturing period:

It is pre-assembled as a block with less than 130 m2 and shipped out in containers, allowing for easy installation. It is a standardized model, so it has a short manufacturing period.

- Integration with pickling line:

With an acid regeneration rate of up to 99%, not only can it be applied to a pickling line producing a small amount of waste acid of 10 to 30 m3 a day, but it is also effective for enhancing or updating ARP facilities. It ensures an efficient and continuous operation of waste acid regeneration push-pull pickling lines (PPL), wire coil pickling lines (WCPL), or other long product pickling lines. Its operation control is entirely integrated in the control system of the pickling line, allowing fully automated operations.

- High eco-friendly performance:

It is designed to achieve the minimum emissions of hydrochloric acid and dust by employing the highly efficient absorber system that recovers hydrochloric acid and iron oxide from the pickling process, as well as the off-gas cleaning system that removes both hydrochloric acid and dust aerosols.

Related Products

-

-

Cold Mill (TCM,CRM)

Steel Plantech proposes a cutting-edge tandem cold mill (4Hi/6Hi) according to the customer’s needs. We can also provide total engineering, including auxiliary equipment such as utility facilities, inspection lines and roll shops.