Starting Joint Development of an Electric Furnace Power Supply System that Contributes to Improving Productivity and Stabilizing Power Systems of Electric Furnace Steelmaking

- 5. Dec, 2022

- Press Release

- Product Information

JP Steel Plantech Co. (hereafter referred to as SPCO) (President: Nobuyuki Nada) and Toshiba Mitsubishi-Electric Industrial Systems Corporation (hereafter referred to as TMEIC) (President: Akira Kawaguchi) have concluded a contract to jointly develop an electric furnace power supply system that contributes to improving productivity and stabilizing power systems of electric furnace steelmaking, and the joint development has commenced.

The new power supply system to be developed jointly will be commercialized from the end of FY2023.

With Japan aiming to achieve carbon neutrality by 2050, there are growing calls for the steel industry to conduct electric furnace steelmaking, which emits relatively small amounts of CO2. It is also necessary to quickly develop large-capacity electric furnaces that can replace the blast furnace-converter method.

However, an electric furnace has a large capacity load that significantly affects power systems. The use of renewable energy, such as solar and wind power generation, will increase in the future, so it will become more important to suppress the generation of voltage flicker and higher harmonics that occurs due to a large change in load.

In order to solve these issues, SPCO and TMEIC, which have advanced knowledge and technologies in the fields of electric furnaces and power electronics, have started developing an electric furnace power supply system that contributes to improving productivity and stabilizing power systems, with the aim of increasing electric furnace capacities and reducing the generation of voltage flicker and higher harmonics. We plan to develop a power supply system that can handle both AC and DC electric furnaces.

JP Steel Plantech Co.:

The company has delivered 150 or more units of electric furnaces in the world, including the eco-friendly, high-efficiency arc furnace ECOARCTM Series, which saves energy and causes less impact on power systems. Its share of delivered electric furnaces is over 50% in Japan.

Under the banner of “Green & Smart” (green: technological innovation to promote decarbonization, smart: making products smart using the latest technology) for 2030, Steel Plantech continues to provide technologies that contribute to people, society, and environment by developing and supplying products and services incorporating the latest technologies.

Toshiba Mitsubishi-Electric Industrial Systems Corporation:

The company has excellent power electronics technologies. In the area of electric equipment for electric furnaces, it provides a wide variety of products, such as transformers for furnaces, flicker-suppressing devices, and rectifier devices. This electric equipment manufacturer boasts top shares in the Japanese market for these products.

Under the banner of “We drive industry,” TMEIC will contribute to customers’ efforts to achieve carbon neutrality by providing products and services that reduce environmental load and promote sustainable growth, such as state-of-the-art power electronics equipment, rotary machines, and automation systems.

Related Products

-

-

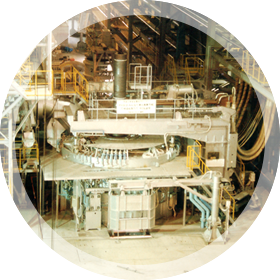

Electric Arc Furnace

Steel Plantech’s electric furnaces for steelmaking are core products succeeded from JFE Engineering (formerly NKK).

Its abundant experience as a steelmaker (or in other words, a user) in addition to technical know-how gleaned from experience in the design and engineering of electric furnaces for steelmaking, accumulated since 1968, enabled the provision not only of electric arc furnaces and auxiliary equipment, but also a wide range of metallurgical and operational technology.

-

-

Ecological and Economical Arc Furnace (ECOARC™)

ECOARC™, the ecological and economical arc furnace developed independently by Steel Plantech, is filled with innovative technology. It comes with advanced scrap preheating technology that eliminates the white smoke and foul odors generated when melting scrap metal, and addresses environmental requirements of the future. Furthermore, it is equipped with melting technology that achieves higher productivity than conventional electric arc furnaces.