Launched demonstration tests of AI electrode control system for steelmaking arc furnaces Contributing to reducing flicker level, power consumption, unit consumption of electrode, and energizing time

- 14. Dec, 2022

- Press Release

- Technical Information

- Product Information

JP Steel Plantech launches demonstration tests of AI electrode control system for arc furnaces.

Attention is being paid to upsizing steelmaking arc furnaces as one of the means to achieve carbon neutrality in the steelmaking industry. However, large voltage fluctuations generated by an arc furnace impact the power source system leading to voltage flickers. For this reason, suppressing variation in arc furnace load is an important issue toward achieving carbon neutrality.

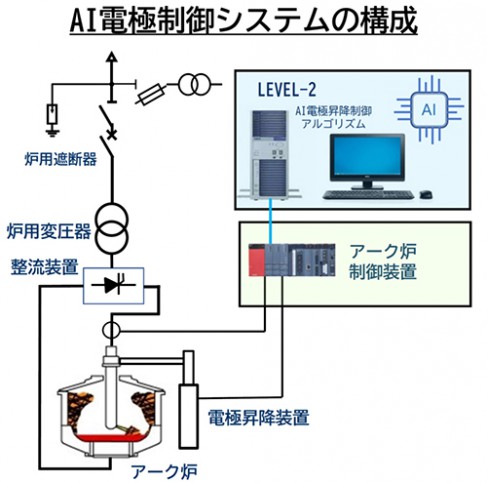

We have been working on developing this electrode control system for arc furnaces with a conventional-type transformer as a technical solution that contributes to reducing the flicker level, energizing time, power consumption, and unit consumption of electrodes. This electrode control system, the key technology in controlling the power supply to the arc furnace, is a complex system where multiple control parameters are linked with many operation data. Adopting AI technology with a reinforcement learning algorithm for controlling this system enables varying dynamically the optimal combination of electrode raising-and-lowering control parameters according to the scrap condition inside the electric arc furnace.

In addition, the other day, we disclosed a new power source system (*) that uses power electronics. If combined with this power system, the electrode control system gains an intelligent control function, which is expected to provide additional favorable effects.

Currently, we have started conducting demonstration tests of this control system using a DC arc furnace, which will become the mainstream of large-scale arc furnaces in the future. We plan to complete the development within this fiscal year. After that, we will also carry out demonstration tests using an AC arc furnace.

Under the banner of “Green & Smart” (Green: Technological innovation to promote decarbonization, Smart: Making products smart using the latest technology), Steel Plantech continues to provide technologies that care for people, society and the environment by developing and supplying products and services incorporating the latest technologies.

(*) For more details, please refer to the press release on December 5, 2022.

https://steelplantech.com/en/news/6406/

Related Products

-

-

Electric Arc Furnace

Steel Plantech’s electric furnaces for steelmaking are core products succeeded from JFE Engineering (formerly NKK).

Its abundant experience as a steelmaker (or in other words, a user) in addition to technical know-how gleaned from experience in the design and engineering of electric furnaces for steelmaking, accumulated since 1968, enabled the provision not only of electric arc furnaces and auxiliary equipment, but also a wide range of metallurgical and operational technology.

-

-

Ecological and Economical Arc Furnace (ECOARC™)

ECOARC™, the ecological and economical arc furnace developed independently by Steel Plantech, is filled with innovative technology. It comes with advanced scrap preheating technology that eliminates the white smoke and foul odors generated when melting scrap metal, and addresses environmental requirements of the future. Furthermore, it is equipped with melting technology that achieves higher productivity than conventional electric arc furnaces.