Received Order to Reconstruct a Vacuum Degassing Apparatus from JSW Steel – Accelerating the Expansion of the Upgrading Business in India

- 6. Nov, 2020

- Press Release

Steel Plantech India Private Limited (head office in Kolkata, India) (hereafter referred to as SPI), an India subsidiary of JP Steel Plantech Co. , a steelmaking plant engineering manufacturer (President: Nobuyuki Nada: head office: Yokohama-shi, Kanagawa), has received an order to reconstruct a 180-t vacuum degassing apparatus (VD) from JSW Steel Ltd. (head office in Mumbai, India).

This work is related to JSW Steel’s plan to move its VD from the current site of Dolvi Works (Maharashtra) to Vijayanagar Works (Karnataka). SPI will disassemble the VD at Dolvi Works and reassemble it at Vijayanagar Works, during which SPI will design the layout and design or manufacture other pieces of equipment, such as utility supply facilities and electric control systems.

Regarding our previous deliveries to JSW Steel, Steel Plantech delivered continuous annealing line (CAL) unit 1 and a continuous galvanizing line (CGL) for Cold Rolling Plant No. 2 of Vijayanagar Works, and a molten pig-iron pre-treatment facility for Steelmaking Plant No. 2 in 2014, as well as delivered CAL unit 2 in 2015. SPI delivered CGL inline pickling facilities in 2015 and a molten pig-iron pre-treatment facility for Steelmaking Plant No. 3 in 2018. We received the order because the customer values our rich experience and project management quality.

Amid growing demand for renewing existing facilities due to deterioration and aging, Steel Plantech is promoting its upgrading business, which increases added value, such as improving productivity and saving manpower using AI, IoT, big data, and robotics. After the COVID-19 pandemic, capital investment is recovering in India, where SPI will be the center for expanding this business.

Related Products

-

-

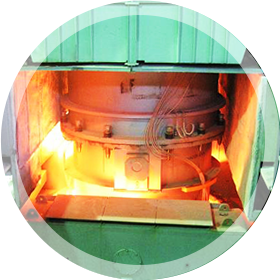

RH Degasser

Molten steel, taken out of the converter furnace, is ultimately refined and degassed during the secondary refining process. The RH Vacuum Degasser is ideal for the swift degassing of large amounts of molten steel. The RH Vacuum Degasser is also suitable for the mass production of high purity steel at integrated steelworks, realizing decarburization and heating by injecting pure oxygen gas into the vacuum vessel. Furthermore, it has extended refining functions, such as the acceleration of desulfurization and deoxidation through addition of flux while controlling the form of the impurities.