Solutions

Product Quality Improvement

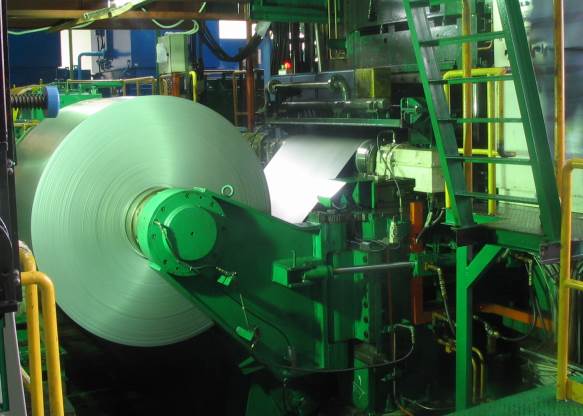

The adoption of the SPEOS™ (Superior Profile with Edge Oriented Shifting) technology developed by Steel Plantech, realizes rolling technology that can both control a strip crown and improve edge drop. Furthermore, optimum, stable concentration control will be possible at the pickling line by utilizing the acid concentration control system.

Lineup

We have provided not only the conventional 4-Hi and 6-Hi mills which are produced based on our rich experience, but also state-of-the-art mills including Zoom-Mill™ and SPEOS™, which Steel Plantech has originally developed by making use of new technologies.

We will suggest the optimal type of rolling mills as well as their layout.

- 1Continuous pickling and cold rolling line that is sequentially connected with the pickling line

- 24-Hi reversible rolling mills that produce high-quality products while cutting down the cost

- 36-Hi reversible rolling mills that are suitable for the rolling of thin materials of various types

- 4Combination mills that have a skin pass function too

- 5Zoom-Mill™ and reverse rolling mill that have high productivity