Solutions

Production Cost Reduction

-

5 % or less

leakage rate

-

30 % reduction

in cooling fan power consumption

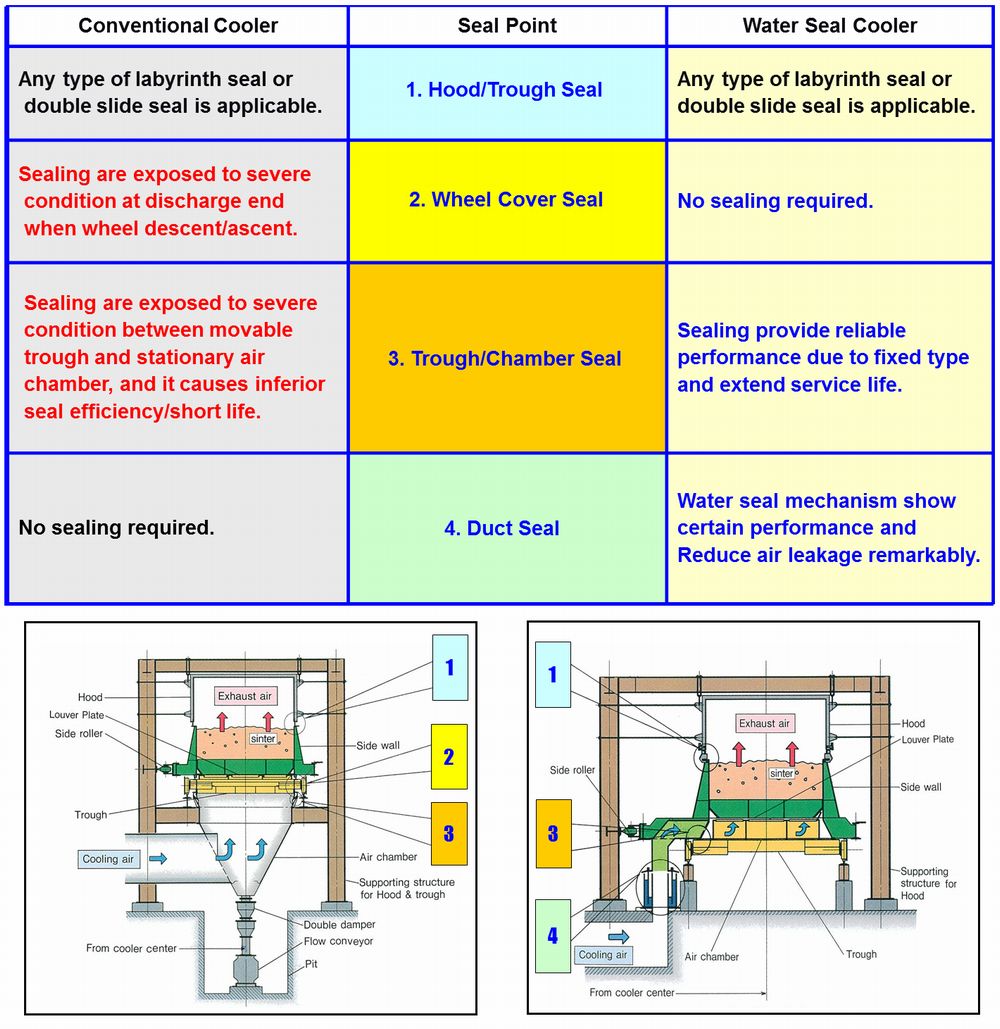

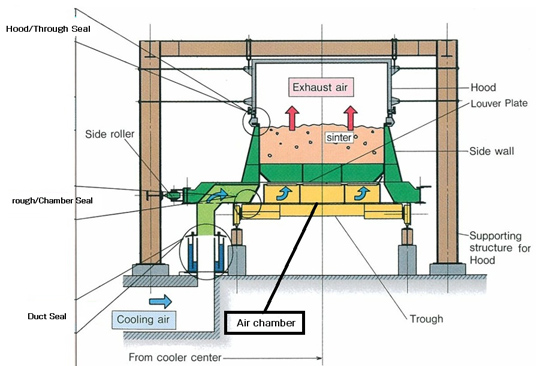

The adoption of a water seal has enabled a significant decrease in air leakage.

This has reduced the amount of air required for cooling to two-thirds of a conventional system, thereby making it possible to keep running costs low.

Environmental Friendliness

The air chamber is built into the trough, significantly reducing dust generation, and making it possible to maintain a clean environment.