Solutions

Product Quality Enhancement

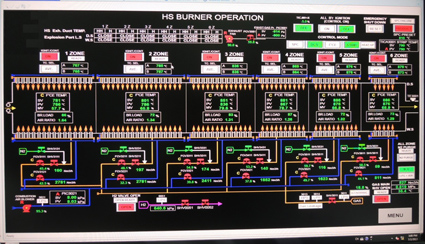

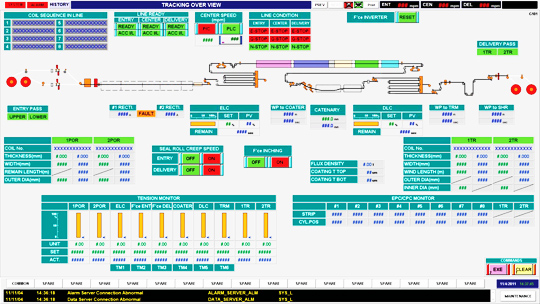

The ACL can be used for annealing temperatures of over 1,000℃ as needed according to variety. It will stabilize quality at a high level through state-of-the-art furnace control and high-precision tension control. What is more, it also offers quality assurance devices such as an online magnetic property measurement, coating thickness meter, sheet thickness meter, sheet width meter, and surface defect meter.

Production Volume Increase

Highly efficient production would be achieved because the coating, baking, and cooling equipment are incorporated into the line. Furthermore, productivity can be enhanced through accurate tension control and stable operation of the line.