Solutions

Product Quality Enhancement

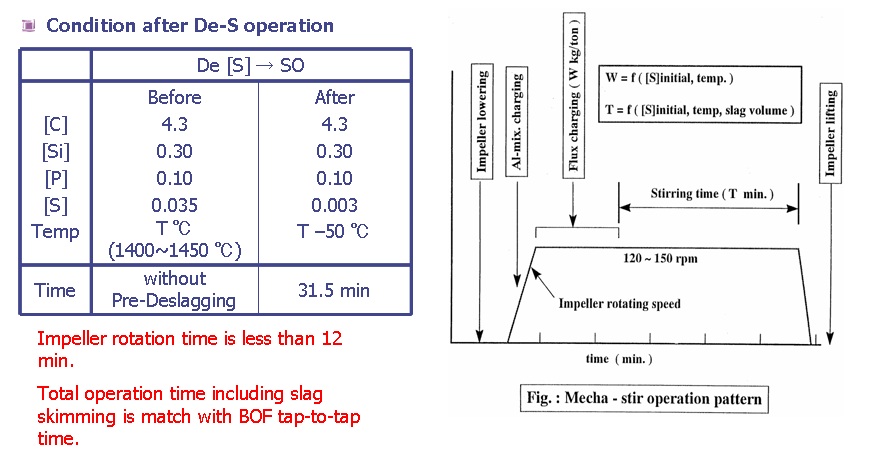

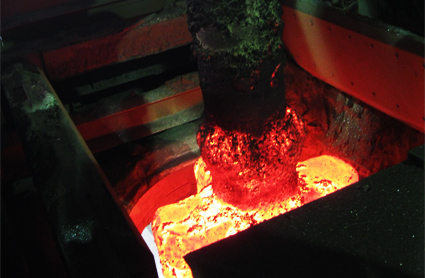

Utilization of the KR Hot Metal Desulfurization System will achieve high-level desulfurization efficiency, curb operating costs and reduce processing time as well as allow high-capacity processing. Furthermore, it will also prove effective in reducing the amount of dust generated.

-

20 %

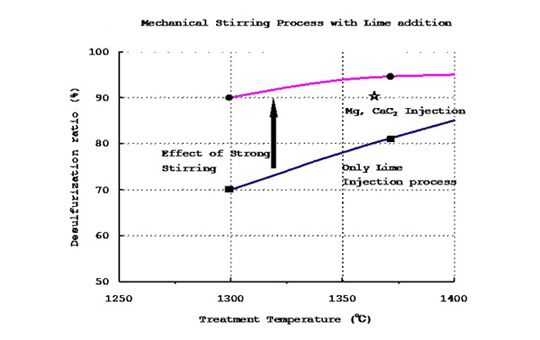

Improvement in Desulfurization Efficiency

Product Quality Enhancement

The KR Hot Metal Desulfurization System achieves roughly 20% higher desulfurization efficiency as compared to powder injection desulfurization.