Technical Information

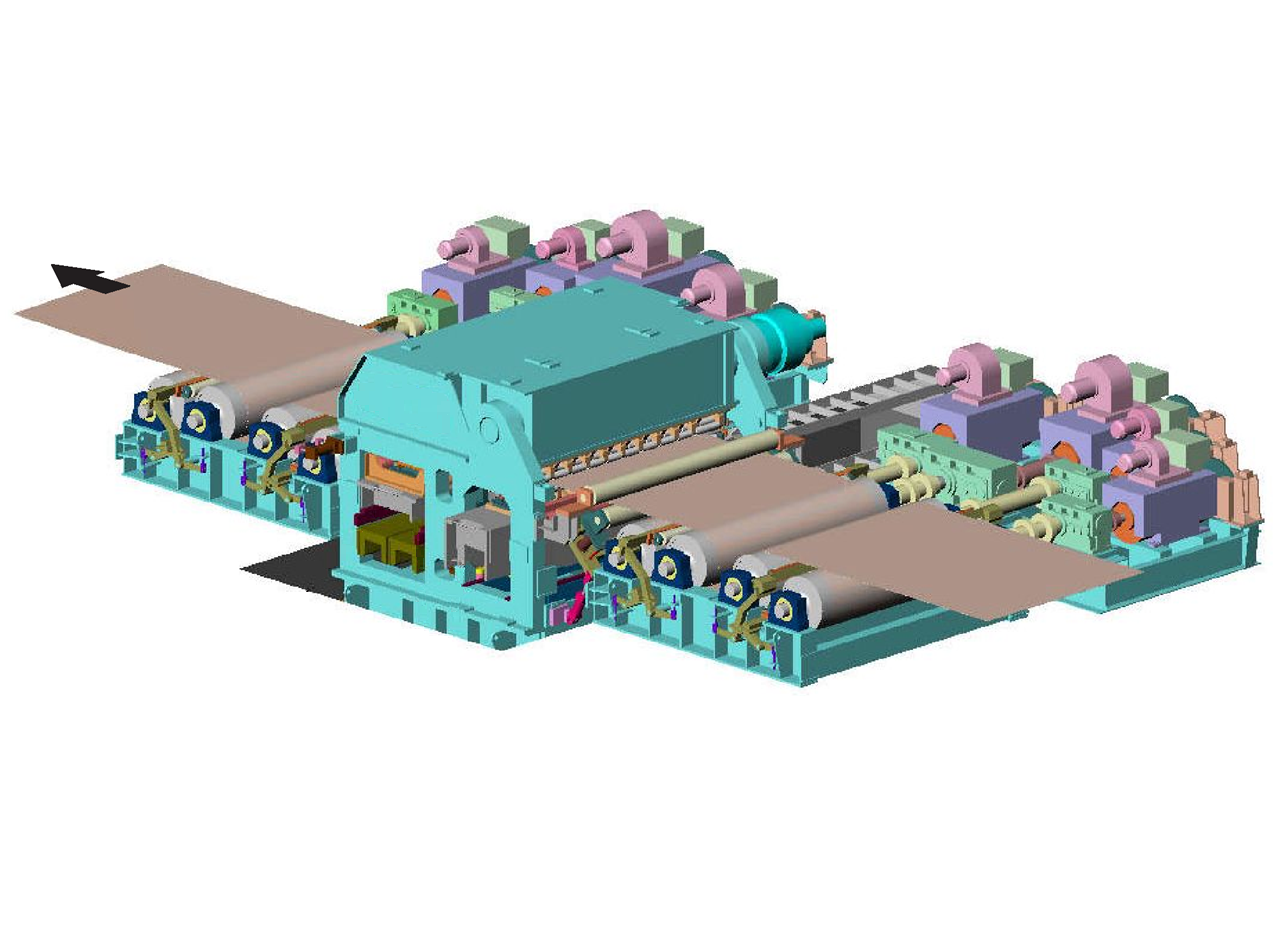

Tension Leveler Roll Helper Drive technology

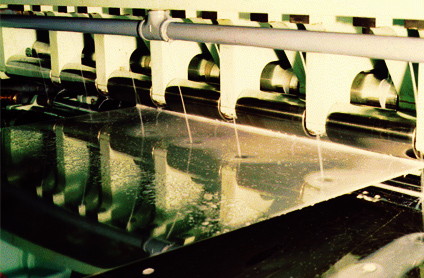

In the case of tension levelers for stainless steel, aluminum and specialized materials, wet leveling is sometimes adopted to prevent marks on the surface made from leveling force.

However, if the materials are soft or if the requirements for the quality of the surface are very severe, there is a need to drive the roll that comes in contact with the board in order to prevent roll slippage.

Steel Plantech is the only company that possesses the technology for driving the small diameter roll of a tension leveler.

Because of roll placement technology, resulting from tests on various materials using test facilities, and differential technologies, such as the helper drive, Steel Plantech is the only company in Japan that currently makes tension levelers.

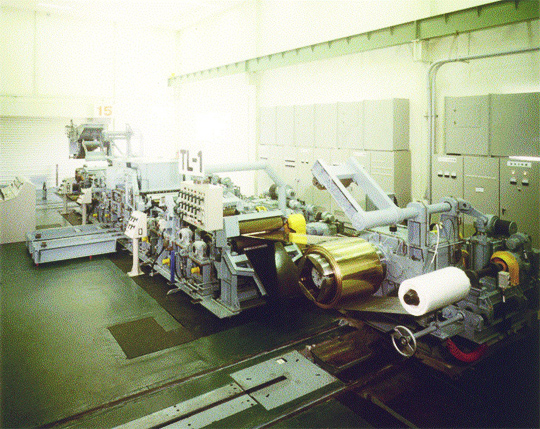

Wet Leveling Technology of Tension Levelers for Stainless Materials

The quality of the surface of the finished product is particularly severe for stainless steel. Marks occurred by leveling force were the biggest challenge in the case of tension levelers for stainless steel.

Our technology for the resolution of this problem was jointly developed with Japanese users, resulting in this leveler. It is currently the de facto standard in Asia of tension levelers for stainless steel.

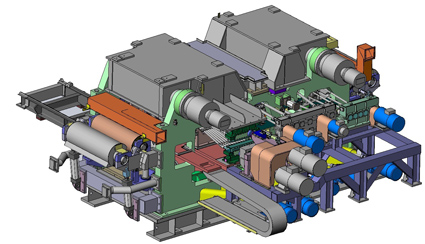

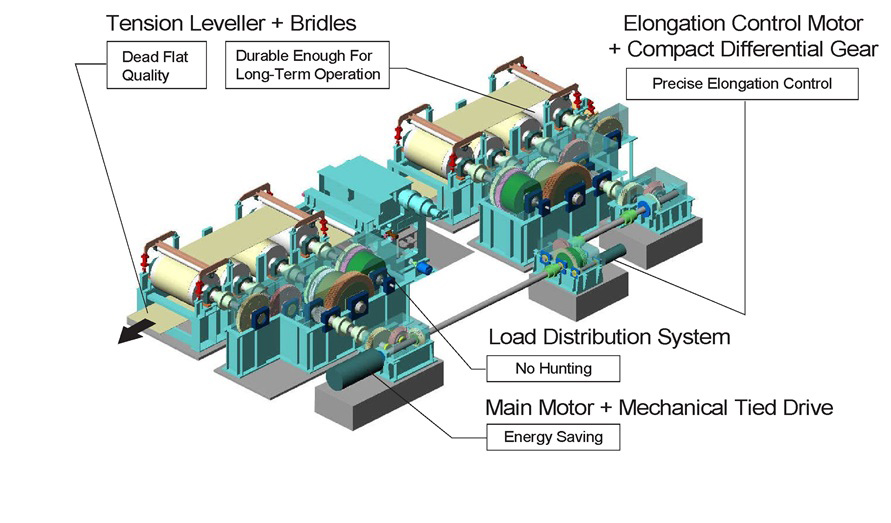

Mechanical Drive Technology for Bridle Rolls—Enabling High Elongation Accuracy Control

Differential gear reducer is used in this drive unit. It provides elongation rate control of a precision that is 30 to 50 times greater to each of two motors—the main motor and elongation rate motor.

This technology is used in ultra-fast lines and lines that require high-grade surface quality.

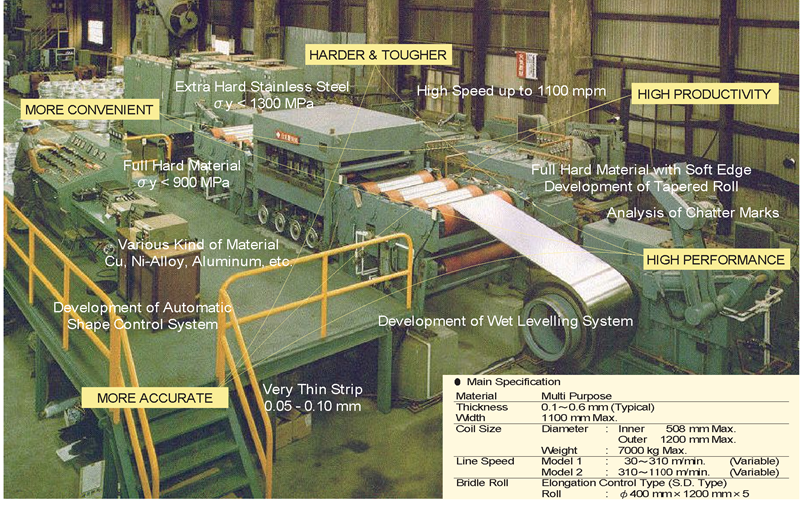

Ultra-fast Tension Leveler Technology

In the past, the maximum speed was 1,200mpm, but a tension leveler with an even higher line speed of 1,340mpm, among the fastest in the world, was supplied in 2006 to JFE Steel East Japan Works (Chiba).

Tension Leveler with Ultra-high Tensile Strength

In 1986, we supplied to the Nippon Steel & Sumikin Stainless Steel Corporation, Hikari Works, a tension leveler with tension of 50 tons, which was the highest at the time.

Currently, we are producing a tension leveler with the world’s top-level tensile strength of 100 tons (world’s top class) for use with 1,500Mpa super-high tensile materials.

Tension Leveler with a Multi-roll Unit for Reduction of Residual Stress and Stabilization of Bow

Tension levelers for aluminum and copper may, depending on the intended use of the materials, require the reduction of residual stress for the next process, such as longitudinal cutting, edging and processing into chips.

The tension leveler with a multi-roll unit was developed for this purpose.

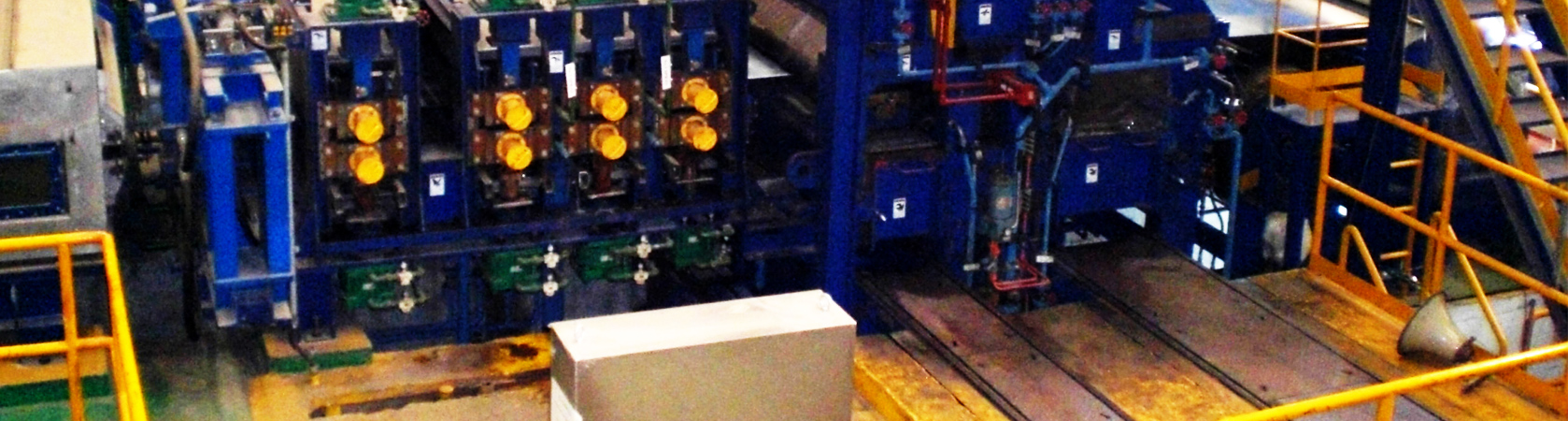

Tension Leveler with Rotational Upper Frame for Easy Maintenance

One of the characteristics of a Steel Plantech tension leveler is that the upper frame can be rotated 180 degrees to enable quick upper roll changes.

This is a feature original to Steel Plantech and cannot be found in the tension levelers of other companies.