Automation of Work to Improve Safety and Achieve Unmanned Operation—Receiving an Order for Hot Rolled Bar Steel Sampling Robot “Spco-ROBO SAMPLER”

- 9. Nov, 2022

- Press Release

- Product Information

In October 2022, we received an order for the hot rolled bar steel sampling robot “Spco-ROBO SAMPLER” (*) for bar steel hot rolling lines of a domestic electric furnace manufacturer.

Currently, the operator collects samples from a cooling bed by cutting off samples at the specified place and carrying them out to conduct various inspections in general. However, this work imposes a high load on operators in terms of temperature and weight.

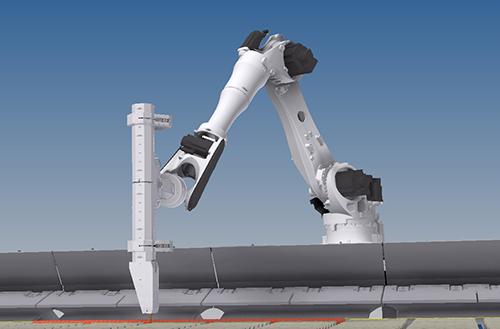

This product is a multi-joint robot placed at the side of a cooling bed. The arm is equipped with a gas cutter and a steel material gripper. This single robot can cut samples with the gas cutter and carry them out.

Spco-LENGTH (*), which is a system that measures the length of a product, determines the cut position by instantly detecting the edge of the material to be cut out using a camera, and then transmits the data to the robot.

Installing this robot automates the work of cutting and carrying out samples. This improves safety and also makes it possible to perform unmanned operation.

In addition, performing sampling without stopping the cooling bed shortens the sampling time, thus improving productivity.

Under the banner of “Green & Smart” (green: technological innovation to promote decarbonization, smart: making products smart using the latest technology), Steel Plantech continues to provide technologies that contribute to people, society, and environment, which is our corporate mission, by developing and supplying products and services incorporating the latest technologies.

*: Smart Products “S-Series”

Spco-ROBO SAMPLER and Spco-LENGTH are products of the Smart Products “S-Series” that are being developed in response to customers’ needs, such as ensuring factory safety and saving labor using robots; improving operation and product quality by using images, AI, and big-data analyses; and providing operation support service based on process analysis.

As of November 2022, 19 products, such as Spco-ROBO KNIGHT and Spco-COUNT, have been placed in the market. We aim to centrally integrate operation rooms, which used to be installed at each plant, and make systems smarter, such as achieving remote operation and one-man operation.

Related Products

-

-

Bar and Wire Rod Mill

Steel Plantech provides the Bar and Wire Rod Rolling System that meet variety of customer needs.

For example, we provide solutions that meet customer needs such as the Slit Rolling System and the High Speed Mill (40m/s) which increase productivity, the Hot Direct Rolling System which is directly connected with a continuous caster, not via a reheating furnace, and thereby greatly reduces the energy consumption, the Water Quenching System which helps in enhancing the strength of bars, and Endless Bar Rolling System (EBROS™) which significantly boosts yield.

Moreover, we can suggest and provide a package solution by supplying integrated lines of electric arc furnaces, continuous casting facility and rolling mills.

-

-

Section Rolling Mill

Rolling mills are facilities that carry out a series of processes including rolling the billets, blooms, slab and beam blanks – extracted from the reheating furnace – into the prescribed size and correcting any bending, cutting them into given lengths, then piling or bundling as needed for shipment. The rolling mills offered by Steel Plantech, with its rich track record of supplying steelmakers in Japan, can meet demanding requirements in terms of production efficiency and product precision.