Completion of the Renewal Work for the Electric Furnace for Stainless Steel at Chita Plant, Aichi Steel Corporation

- 30. May, 2023

- Press Release

- Product Information

JP Steel Plantech Co., the steelmaking plant engineering manufacturer (head office in Yokohama-shi, Kanagawa; President and Representative Director: Keiji Wakahara), has completed the renewal work for an electric furnace for stainless steel at the Chita Plant of Aichi Steel Corporation. The facility is now smoothly operating.

This work modified and renewed mechanical equipment such as aged furnace shells as well as replaced the accompanying control system with a state-of-the-art system.

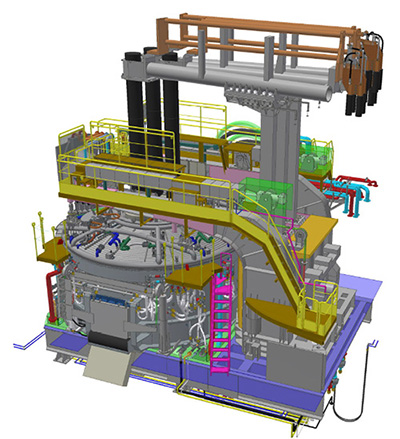

Regarding the mechanical equipment, we made the furnace diameter as large as possible, made the furnace cover larger, and modified related parts. We also carried out many other modifications and renewals, including partial renewal of the electrode lifting device and the tilting mechanism as well as replacement of the piping around the furnace and the deck.Since the existing equipment was installed long ago and some information such as drawings had been lost, we fully utilized three-dimensional point group data that had been obtained by measurement prior to the work. High-precision design of the entire furnace system was carried out with the help of 3D CAD software, which helped us to complete and deliver the work smoothly.

For the control system, we constructed a system (IoT platform) that can accumulate and analyze operation data as part of DX and integrated all control functions on monitors (HMI).

In addition, we introduced an automatic control function, AUTO-ARC (automatic operation system). Applying our original Smart Hot-spot Control, which makes the system efficient by supplying best-fit electric power, improves the unit power consumption, contributing to achieving carbon neutrality.

We have rich knowledge of electric furnaces, including the eco-friendly high-efficiency arc furnace ECOARC™ Series. By integrating this knowledge with the latest technologies, we will respond to customers’ needs and provide more environmentally friendly electric furnaces.

Related Products

-

-

Computer System for Steelmaking Facilities

Automatic operation system is necessary for Melt Shop in order to achieve more efficient and stable operation. For the solution to such a needs, Steel Plantech offers the AUTO-ARC (for Electric Arc Furnace) and AUTO-LF (for Ladle Furnace) as high quality and low price computer system.

Both the AUTO-ARC and AUTO-LF provide not only automatic power input control but also a wide variety of functions for the improvement and standardization of your operations, including management functions such as monitoring and control of the facility, data collection, operation report, daily report, monthly logs, and statistical analysis of the collected performance data.

-

-

Electric Arc Furnace

Steel Plantech’s electric furnaces for steelmaking are core products succeeded from JFE Engineering (formerly NKK).

Its abundant experience as a steelmaker (or in other words, a user) in addition to technical know-how gleaned from experience in the design and engineering of electric furnaces for steelmaking, accumulated since 1968, enabled the provision not only of electric arc furnaces and auxiliary equipment, but also a wide range of metallurgical and operational technology.