Resolving concerns about high power supply all at once — launching sales promotion activities for the new power supply system, “CleanArc,” in October

- 4. Oct, 2023

- Press Release

- Product Information

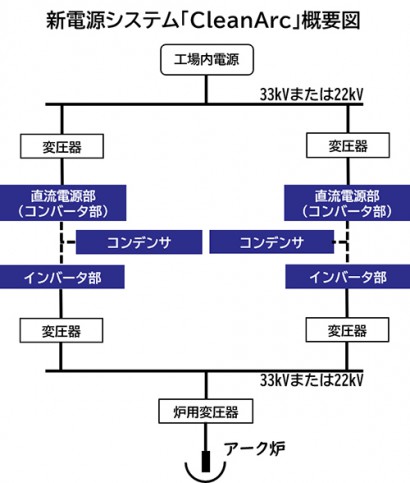

In October 2023, JP Steel Plantech Co. (head office in Yokohama, Kanagawa; President and Representative Director: Keiji Wakahara) and Toshiba Mitsubishi-Electric Industrial Systems Corporation (TMEIC) (head office in Chuo-ku, Tokyo; President: Akira Kawaguchi) will launch sales promotion activities for the new electric furnace power supply system, “CleanArc,” which contributes to improving productivity and stabilizing power systems of electric furnace steelmaking equipment.

With Japan aiming to achieve carbon neutrality by 2050, there are growing calls for using the electric furnace steelmaking process. However, since operation of electric furnaces requires a large amount of electric power, it is necessary to take measures for reducing flicker and harmonics that affect the electric power company’s power supply system.

The new power supply system, “CleanArc,” will resolve these concerns all at once.

The input power is stabilized by using TMEIC’s original inverter, which employs IEGT devices (*), and these IEGTs are also used in the DC power supply section (converter). Consequently, almost no flicker or harmonics occur, and no large power supply equipment is required to suppress these phenomena. Moreover, the high-speed constant current control stabilizes arc generation, which inhibits arc interruption, contributing to improving productivity.

Furthermore, it is possible to add the uniform melt promotion function of Smart Hot-spot Control and the additional charge determination optimization function based on scrap volume measurement, both provided by the Steel Plantech’s original melt control system, “AutoArc.” CleanArc can reduce unit power consumption by approximately 10%, and unit consumption of electrodes by 5 to 10% (both compared with those values of Steel Plantech’s conventional products).

This revolutionary system is compatible with all AC (alternating current) electric furnaces regardless of furnace capacity. Moreover, this new power supply system can be installed in most places without restrictions; prior installation work can be carried out while the plant is in operation; and downtime can be minimized. Furthermore, since influence on the power supply system can be significantly reduced, renewable energy, which is expected to be increasingly available, becomes a candidate for the power source.

We will also develop a power supply system for DC (direct current) electric furnaces to help all electric furnace users achieve carbon neutrality.

(*) IEGT device: A power device that can control high voltages and large currents. IEGT is an acronym for Injection Enhanced Gate Transistor.

For the announcement of launching the joint development, refer to the press release on December 5, 2022 (https://steelplantech.com/en/news/6406/)

Related Products

-

-

Computer System for Steelmaking Facilities

Automatic operation system is necessary for Melt Shop in order to achieve more efficient and stable operation. For the solution to such a needs, Steel Plantech offers the AUTO-ARC (for Electric Arc Furnace) and AUTO-LF (for Ladle Furnace) as high quality and low price computer system.

Both the AUTO-ARC and AUTO-LF provide not only automatic power input control but also a wide variety of functions for the improvement and standardization of your operations, including management functions such as monitoring and control of the facility, data collection, operation report, daily report, monthly logs, and statistical analysis of the collected performance data.

-

-

Electric Arc Furnace

Steel Plantech’s electric furnaces for steelmaking are core products succeeded from JFE Engineering (formerly NKK).

Its abundant experience as a steelmaker (or in other words, a user) in addition to technical know-how gleaned from experience in the design and engineering of electric furnaces for steelmaking, accumulated since 1968, enabled the provision not only of electric arc furnaces and auxiliary equipment, but also a wide range of metallurgical and operational technology.

-

-

Ecological and Economical Arc Furnace (ECOARC™)

ECOARC™, the ecological and economical arc furnace developed independently by Steel Plantech, is filled with innovative technology. It comes with advanced scrap preheating technology that eliminates the white smoke and foul odors generated when melting scrap metal, and addresses environmental requirements of the future. Furthermore, it is equipped with melting technology that achieves higher productivity than conventional electric arc furnaces.