JP Steel Plantech Co. receives order for the eco-friendly high-efficiency arc furnace ECOARC-light™ for the Osaka Unit Sakai Works of Osaka Steel Co., Ltd.

- 26. Jan, 2024

- Press Release

- Product Information

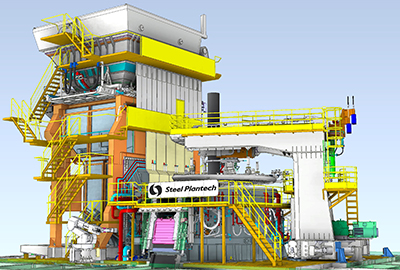

JP Steel Plantech Co. (“SPCO”), a steelmaking plant engineering manufacturer (head office in Yokohama, Japan; President and CEO, Representative Director: Keiji Wakahara), received an order for the eco-friendly high-efficiency arc furnace ECOARC-light™ for the Osaka Unit Sakai Works of Osaka Steel Co., Ltd. This electric furnace is scheduled to start operations in the second half of FY 2025.

ECOARC-light™ is a product from the ECOARC™ Series (*1) that can significantly reduce the power consumption of electric furnaces, and has been developed for the purpose of modification of an existing furnace. By making full use of the existing equipment in the plant, ECOARC-light™ can minimize the initial investment cost and shorten the installation time, while still reducing the power consumption by 80 kWh/t (compared with our conventional electric furnaces).

Moreover, this product is expected to reduce production costs because it can use inexpensive scrap as raw material.

This is the second ECOARC-light™ sold. For the delivery of this facility, we will revise the shape of its shaft based on our accumulated knowledge to increase its scrap preheating effect because it has a much larger capacity than the first facility sold (which has already been delivered to another customer).

To increase operational efficiency, the facility will be equipped with three devices from the Smart Products S-Series (*2): Spco-ROBO KNIGHT, the molten-steel sampling and temperature measuring robot; Spco-EcoLaserNavi, the laser exhaust gas analyzer that gives feedback on the control of oxygen and carbon injection and other furnace operations, while detecting water leaks in the furnace; and Spco-SAND, the automatic sand filling device for the tap hole.

By combining ECOARC-light™, which can reduce the impact on the environment by improving energy efficiency, and Smart Products, which can achieve substantial labor savings, the electric arc furnace will not only enhance cost-competitiveness through cost reductions but also help solve sustainability challenges, such as decarbonization and work style reform.

Under the banner of “Green & Smart” (“Green”: technological innovation to promote decarbonization; “Smart”: making products smart using the latest technology), SPCO will continue to provide technologies respectful to people and the environment by developing products and services incorporating the latest technologies.

(*1) ECOARC™ Series

The ECOARC™ Series is a line of eco-friendly high-efficiency arc furnaces that can significantly reduce power consumption compared with our conventional electric furnaces, offering three products—ECOARC™, ECOARC-light™, and ECOARC-FIT™—to meet different needs for the building of furnaces.

The most important feature of the ECOARC™ Series is that they utilize the thermal energy of exhaust gas generated in the melting process for iron scrap to preheat iron scrap at high temperatures. As these furnaces can produce molten steel with less energy, they can not only reduce power consumption and CO₂ emissions but also reduce the impact on the environment by, for example, decreasing noise and eliminating white smoke with the exhaust gas treatment equipment.

In recognition of these benefits and strengths, the series was adopted by Japan’s Agency for Natural Resources and Energy as advanced equipment/systems in “(A) Advanced Projects” under the Subsidies for the Support Program to Promote Investments in Advanced Energy Conservation.

As of January 2024, a total of 11 facilities (seven in Japan and four overseas) of this series have been sold, out of which eight are in operation.

(*2) Smart Products S-Series

The Smart Products S-Series is a group of products that, in response to customers’ needs, are being developed in areas such as: ensuring factory safety and achieving labor-savings using robots; improving operation and product quality by using images, AI, and big-data analyses; and providing operational support service based on process analysis. We aim to centrally integrate operations rooms, which used to be installed at each plant, and make systems smarter, by methods such as remote operation and one-man operation.

Rendering of ECOARC-light™

Related Products

-

-

Ecological and Economical Arc Furnace (ECOARC™)

ECOARC™, the ecological and economical arc furnace developed independently by Steel Plantech, is filled with innovative technology. It comes with advanced scrap preheating technology that eliminates the white smoke and foul odors generated when melting scrap metal, and addresses environmental requirements of the future. Furthermore, it is equipped with melting technology that achieves higher productivity than conventional electric arc furnaces.