Hot Run of OG System in Usiminas Ipatinga Plant after Revamping Work

- 16. Oct, 2023

- Press Release

- Product Information

Hot run of the OG system* in Usiminas Ipatinga Plant supplied by JP Steel Plantech Co. (SPCO) was completed (one in July 2023, one in September 2023).

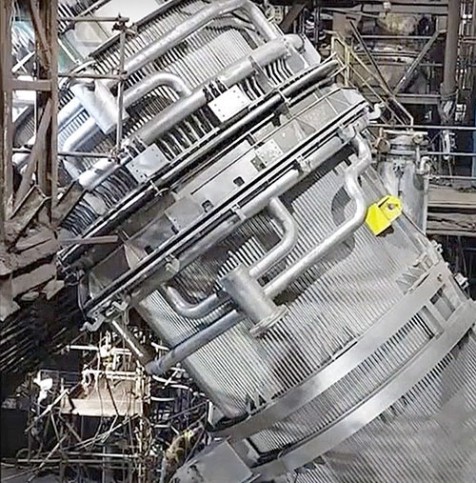

This work revamps the cooler and dust collector of the OG systems at the second steelmaking plant in Ipatinga.

Due to the high evaluation of the systems installed in the past, SPCO received the order in February 2021.

For the cooler, the cooling system has been sealed to stabilize converter operation, and for the dust collector, the secondary dust collector (RSE) and the induced draft fan (IDF) have been renewed to enhance the compliance with environmental regulations.

In spite of the remote location and the spread of coronavirus, SPCO made full use of 3D CAD design and remote engineering, meeting the project deadline.

Adjustments related to the controller of the entire OG system have also been performed, contributing to smooth operation of the systems.

SPCO has supplied 193 OG systems around the world (86 in Japan, 107 overseas) as of October 2023, and SPCO’s share of this system in Japan is 100%. Many of these OG systems have been operated for more than 50 years and need to be revamped.

Facing the increasing demand for decarbonization, SPCO will actively work on reducing greenhouse gases and making the environment clean by proceeding with revamps and renewals of the steel related facilities.

Chimney outlet gas after revamp. The emitted gas is clear, indicating improvement of the OG dust collection performance (white part of the background in the photo is cloud).

*OG system (OG = Oxygen Converter Gas Recovery System)

OG system is a system to recover carbon monoxide, emitted from a converter during operation, without combustion as much as possible (before it turns into carbon dioxide). After cooling and dust removal, highly concentrated (70-80%) CO gas is stored in a gas holder and effectively used as fuel.

Related Products

-

-

OG System

The OG system (Oxygen Converter Gas Recovery System) is suppressed type LD gas recovery system for the converters of steel makings shops. The OG system was jointly developed and improved by both Nippon Steel Corporation (NSC/ now NSSC) and Kawasaki Heavy Industries Ltd. (KHI), in Japan. In 2004, steel plant division of KHI was transferred to JP Steel Plantech, Co (SPCO).

Therefore, SPCO and NSC have developed the technologies and own the patents of the OG system. Until now, totally 192 OG systems have been installed in all over the world, thus the name of “OG” is widely admitted not only as the safest process for recovering LD gas with high efficiency but also as a synonym of the best solution for energy saving and environmental control.