Business Alliance between Steel Plantech and Inductotherm Group Japan

- 27. Sep, 2021

- Press Release

- Technical Information

Steel Plantech Corporation (President: Nobuyuki Nada; head office: Kohoku-ku, Yokohama) and Inductotherm Group Japan Ltd. (President: Shaun LeMarbre; head office: Nishi-ku, Kobe) have concluded a business alliance agreement on the sales of the electromagnetic induction melting furnace (EIF), which is Inductotherm Group Japan’s main product, and plant engineering.

The Japanese Government aims to achieve carbon neutrality by 2050. In order to help achieve that target, we will contribute to greening (decarbonizing) the areas of steelmaking, non-ferrous metals, formed raw material, and metal recycling by providing metal refining processes that use clean electric energy.

Inductotherm Group Japan was established in 1982 as the Japanese subsidiary of Inductotherm Group (based in New Jersey, USA), which has 40 companies in 19 countries around the world. Inductotherm Group has the largest market share of EIF in the world. Based on its original induction melting/heating design concept, the Group designs and manufactures high-efficiency large-capacity induction systems and provides knowledge on processes and after-sales services all over the world.

Established in 2001 by integrating the steelmaking and machinery businesses of four founding mother companies (JFE Engineering, Hitachi Zosen, Kawasaki Heavy Industries, and Sumitomo Heavy Industries), Steel Plantech is a general plant manufacturer that covers the areas of pig-iron making, steelmaking, continuous casting, rolling, and surface treatment. Throughout its history, including the time prior to the merger of the mother companies, the company has delivered over 100 units of electric arc furnaces (EAF), one of its main products, in and outside Japan. In 2021, its eco-friendly high-efficiency arc furnace ECOARC™ was certified by the Ministry of the Environment as an advanced equipment/system in the Subsidies for the Support Program to Promote Investments in Advanced Energy Conservation. Since 2018, it has been developing smart products utilizing AI and robotics, as well as technologies to improve productivity and quality and achieve fully automated operation in the areas of electric furnaces, continuous casting, and rolling.

This alliance enables the integration (fusion) of the high-performance EIF technologies owned by Inductotherm Group Japan and the engineering technologies of melting and refining processes using EAFs and smart products owned by Steel Plantech. By sharing the value of “Green & Smart” with customers, we will contribute to realizing a decarbonized society through the integrated technologies of both companies.

■ Outline of business alliance

· Date of business alliance agreement: Wednesday, September 22, 2021

· Area of cooperative activities: Within Japan

· Cooperative activities: Business activities of both companies and joint processing of orders

· Scope of cooperative activities

JP Steel Plantech Co.:

- Engineering and management of the whole project

- Peripheral equipment of induction furnaces or their services

- Automation of robots and the entire automation system

Inductotherm Group Japan Ltd.:

- Main body and system of the induction furnace

Inductotherm Group Japan’s “Electromagnetic Induction Furnace” (volumes 1 and 2)

Related Products

-

-

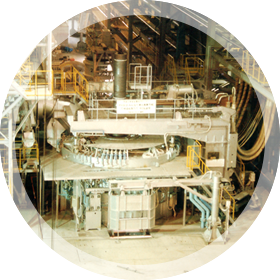

Electric Arc Furnace

Steel Plantech’s electric furnaces for steelmaking are core products succeeded from JFE Engineering (formerly NKK).

Its abundant experience as a steelmaker (or in other words, a user) in addition to technical know-how gleaned from experience in the design and engineering of electric furnaces for steelmaking, accumulated since 1968, enabled the provision not only of electric arc furnaces and auxiliary equipment, but also a wide range of metallurgical and operational technology.

-

-

Ecological and Economical Arc Furnace (ECOARC™)

ECOARC™, the ecological and economical arc furnace developed independently by Steel Plantech, is filled with innovative technology. It comes with advanced scrap preheating technology that eliminates the white smoke and foul odors generated when melting scrap metal, and addresses environmental requirements of the future. Furthermore, it is equipped with melting technology that achieves higher productivity than conventional electric arc furnaces.