Eco-Friendly High-Efficiency Arc Furnace ECOARC™ and Turn Coil Technology Adopted as Advanced Equipment/Systems under the FY2021 Subsidies for the Support Program to Promote Investments in Advanced Energy Conservation

- 25. May, 2021

- Technical Information

- Product Information

With “Green & Smart” as a keyword, Steel Plantech is promoting technological innovation to achieve decarbonation (green innovation) and the utilization of DX, AI, and robotics (smart technology).

On May 24, 2021, our eco-friendly high-efficiency arc furnace ECOARC™ and electromagnetic agitation technology using a coil at the bottom of the arc furnace (*) (hereinafter, “turn coil”) were adopted as advanced equipment/systems under the FY2021 Subsidies for the Support Program to Promote Investments in Advanced Energy Conservation. With the goal of achieving carbon neutrality in 2050, the Agency for Natural Resources and Energy identifies advanced technologies with high energy-saving potential from the market, and grants subsidies to them intensively. When a business operator installs an advanced equipment/system that is eligible for this program, half or two-third of the cost of equipment is subsidized if they meet certain energy-saving requirements.

ECOARC™ reduces unit power consumption significantly with a high-efficiency preheating shaft, while the turn coil reduces it by agitation. They were adopted because these features were highly evaluated.

Last month, we announced the development of ECOARC-FIT™ that offers higher versatility in equipment installation to expand the product lineup of the ECOARC™ series.

We will contribute to realizing a decarbonized society by recommending our customers to use this subsidy program and by providing our energy-saving technology widely.

* Electromagnetic agitation technology using a coil on the arc bottom

A copper tube coil is placed on the bottom of a DC electric furnace. Magnetic fields generated by this coil agitate molten steel to reduce unit power consumption by 10 kWh/t.

Related Products

-

-

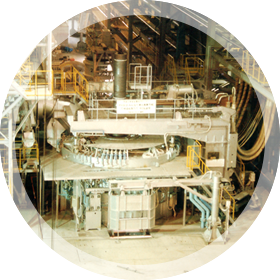

Electric Arc Furnace

Steel Plantech’s electric furnaces for steelmaking are core products succeeded from JFE Engineering (formerly NKK).

Its abundant experience as a steelmaker (or in other words, a user) in addition to technical know-how gleaned from experience in the design and engineering of electric furnaces for steelmaking, accumulated since 1968, enabled the provision not only of electric arc furnaces and auxiliary equipment, but also a wide range of metallurgical and operational technology.

-

-

Ecological and Economical Arc Furnace (ECOARC™)

ECOARC™, the ecological and economical arc furnace developed independently by Steel Plantech, is filled with innovative technology. It comes with advanced scrap preheating technology that eliminates the white smoke and foul odors generated when melting scrap metal, and addresses environmental requirements of the future. Furthermore, it is equipped with melting technology that achieves higher productivity than conventional electric arc furnaces.