JP Steel Plantech Co. exhibits at the METEC 2019 to strengthen presence at overseas.

- 8. Jul, 2019

- Event Information

- Press Release

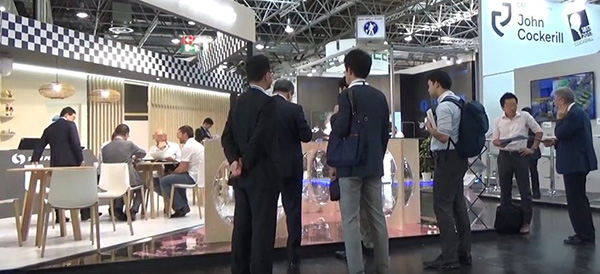

JP Steel Plantech Co. (SPCO) has attended, with a booth and presentation of technical papers, METEC 2019 (International Metal Manufacturing / Metallurgy Technology Exhibition / Conference), a trade fair at Dusseldorf, from 25th June 2019 to 29th June 2019 for steelmaking and steel production plants and equipment which is held once every four years.

The number of visitors who came to the SPCO’s booth was increased by 180% compared to the previous time (2015), and many business discussions were carried out.

Number of inquiries on the “market launch time” and “merits expected” regarding SPCO’s SMART PRODUCTS, “S-Series”, were made during such discussion which has encouraged us to accelerate our development of our “S-Series” equipment lineup.

The lineup equipment “S-Series” is a collective term for SMART PRODUCTS that SPCO has been developing with the concept of enhancing value-added “Products” and “Services” of existing equipment using AI and IoT technologies.

The presentation of technical papers at the conference referring to the combination of “Hot Skin Pass Mill” and “Tension Leveler”, “Zoom-Mill ™” and “PL-TCM” attracted keen interest.

In addition, as a noticeable feature for this time, the number of visitors from India, where the steel production is rapidly expanding, increased. Together with our subsidiary company, Steel Plantech India Pvt. (*1) we have carried out fruitful meetings.

Together with John Cockerill Industry (*2) which had booth adjacent to SPCO’s booth, SPCO promoted business discussion with visitors for each company’s area of business.

Following the “AISTech” steel exhibition held in Pittsburgh (USA) in May and the “SEAISI” conference held in Bangkok (Thailand) in June this year, through attending this METEC 2019 SPCO intends to strengthen its presence in the international market to expand its business.

(*1): Steel Plantech India Pvt. (SPI) was established in 2011 as our first subsidiary company in India, it became a wholly-owned manufacturing and sales subsidiary company in 2016, not only developing SPCO’s business, but its own business for customers in South Asia including India. SPCO is also utilizing SPI as a procurement base.

Company name: Steel Plantech India Pvt. Ltd. (SPI)

Location: Infinity Benchmark Building, 14th Floor, Unit: 1403, Block-EP & GP, Sector-V, Salt Lake City, Kolkata – 700091,

IndiaRepresentative: Shinichiro Sakai

Established: 2011

Capital: 40,000,000 rupees

Number of employees: Approximately 50

(*2): John Cockerill Industry designs, supplies and modernizes cold rolling mills, processing lines, chemical and thermal treatment installations for the steel and the non-ferrous industry. SPCO made Cooperation Agreement in July 2018 in the field of Pickling Lines with Tandem Cold Mills for the steel industry and particularly for the Advanced High Strength Steel (AHSS) market.

Related Products

-

-

Temper /

Skin Pass MillsThe device uses skin pass rolling to improve the mechanical properties and surface texture, and improve flatness, in order to form materials such as hot-rolled steel sheets, cold-rolled steel sheets, stainless steel plates, and aluminum plates into final products. Since it conducted tests with its own test equipment in 1965, Steel Plantech has continued to develop theories and deliver actual devices. As a result, the company has delivered 63 skin pass mills worldwide up to this point in time.

-

-

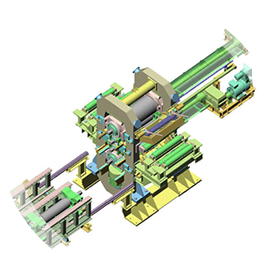

Zoom-Mill™

Steel Plantech can propose cold rolling mills (CRM) or state-of-the-art tandem cold mills (TCM) according to the customer’s needs. Furthermore, the ZOOM (zero oriented off-gauge minimization) function developed by Steel Plantech can be added to improve yield ratios and reduce production costs as compared to conventional CRMs.

-

-

Tension Leveler

Tension levelers level and improve the flatness of materials such as hot rolled steel, cold rolled steel, stainless steel, aluminum, copper and specialized materials, and finish them into a final product. The range of the materials that can be used for leveling are those with a thickness of between 0.05mm-8.0mm, a width of between 300m-2,300mm and a yield strength of between 50MPa-1,500MPa. Tests of various materials using original testing equipment have been carried out on Steel Plantech’s tension levelers since 1970. Theories have been constructed, tested, and supply of tension levelers made, with this repeated many times over the years. 194 sets have been supplied around the world, practically making Steel Plantech a specialist in tension levelers.

-

-

Cold Mill (TCM,CRM)

Steel Plantech proposes a cutting-edge tandem cold mill (4Hi/6Hi) according to the customer’s needs. We can also provide total engineering, including auxiliary equipment such as utility facilities, inspection lines and roll shops.