JP Steel Plantech Participates in METEC 2019 and Releases a Technical Paper

- 19. Jun, 2019

- Event Information

- Press Release

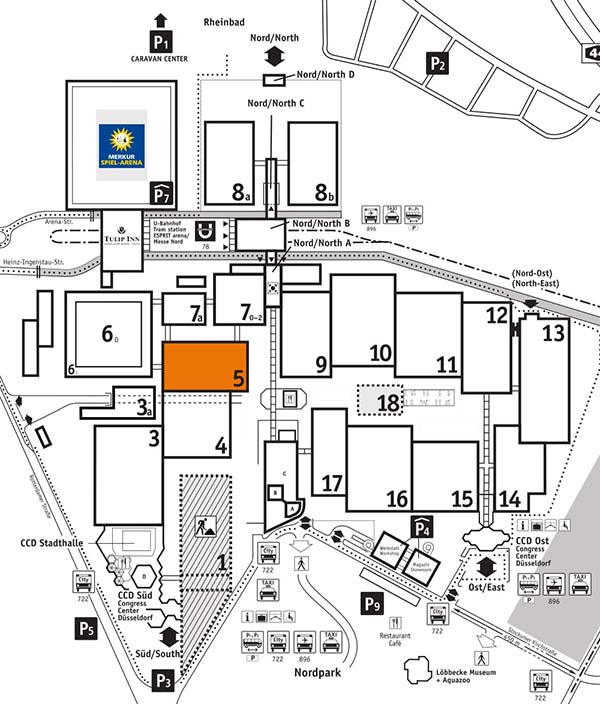

JP Steel Plantech Co., a steelmaking plant engineering manufacturer (President: Nobuyuki Nada; head office: Yokohama-shi, Kanagawa), will participate as an exhibitor at the International Metallurgical Trade Fair with Congresses (METEC) 2019 on June 25 (Tue) to 29 (Sat), 2019. METEC is the trade fair for iron/steelmaking plants/facilities held once every 4 years in Düsseldorf, Germany. We will participate in this trade fair as we did in the last one.

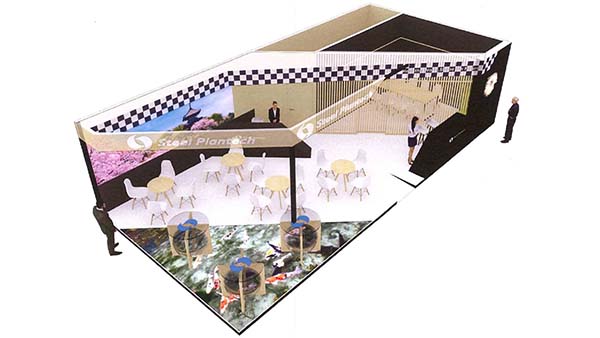

In addition to our main products such as electric furnaces, steel sheet rolling machines, process lines, and process equipment, we will show the Smart Products that we are developing using the latest technologies, such as AI, IoT, and big data, on tablets and technical papers at the booth. The booth will be decorated with a Japanese design. Japanese sceneries will be projected on the walls between product presentation movies, and clips of typical Japanese sceneries such as cherry blossoms, Mt. Fuji, and dry landscape gardens will be shown on the floor. Japanese tea and sweets will be served to visitors. By using a strong Japanese theme, we hope to express our concept of collecting and developing technologies “made of Japan.”

We concluded a business alliance agreement with the John Cockerill Group (former Cockerill Maintenance & Ingénierie SA), a Belgian general heavy machinery manufacturer of products such as high-quality continuous pickling cold rolling lines for the high-tensile steel market, on July 3 last year. Our booth in this exhibition will be set up opposite them to clearly show our alliance.

In addition, to promote our technologies to the world, we will also present our technical papers on PL-TCM (13:40 on Wednesday, June 26, jointly with the John Cockerill Group); Zoom-Mill™ (12:20 on Thursday, June 27); and Hot Skin Pass Mill & Tension Leveler Line (14:40 on Thursday, June 27).

- Outline of International Metallurgical Trade Fair with Congresses (METEC) 2019

Name: International Metallurgical Trade Fair with Congresses (METEC) 2019

Period: 9:00 to 18:00 on June 25 to 29, 2019 (to be closed at 16:00 on the last day)

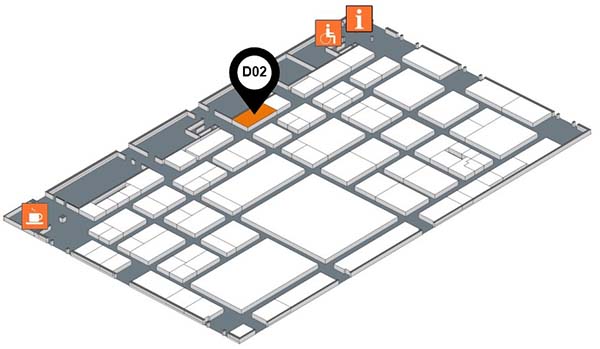

Location: Halls 3 to 5, Messe Düsseldorf

Organizer: Messe Düsseldorf GmbH

- Presentation of technical papers

13:40 to 14:00 on June 26 (Wed) in Room 27

Title: State-of-the-art PL-TCM (Pickling Lines and Tandem Cold Strip Mills)

Presenter: Tanehiro Kikkawa, Chief Engineer, Rolling/Process Sector, JP Steel Plantech Co.

* Joint presentation with the John Cockerill Group (former Cockerill Maintenance & Ingénierie SA)

12:20 to 12:40 on June 27 (Thu) in Room 28

Title: Zoom-Mill™ for Reversible Cold Rolling

Presenter: Tanehiro Kikkawa, Chief Engineer, Rolling Process Sector, JP Steel Plantech Co.

14: 40 to 15:00 on June 27 (Thu) in Room 28

Title: Hot Skin Pass Mill & Tension Leveler Line for Ultra High Strength Steel

Presenter: Hiroyuki Uematsu, Corporate Planning & Administration Department, JP Steel Plantech Co.

Related Products

-

-

Temper /

Skin Pass MillsThe device uses skin pass rolling to improve the mechanical properties and surface texture, and improve flatness, in order to form materials such as hot-rolled steel sheets, cold-rolled steel sheets, stainless steel plates, and aluminum plates into final products. Since it conducted tests with its own test equipment in 1965, Steel Plantech has continued to develop theories and deliver actual devices. As a result, the company has delivered 63 skin pass mills worldwide up to this point in time.

-

-

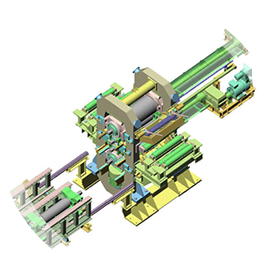

Zoom-Mill™

Steel Plantech can propose cold rolling mills (CRM) or state-of-the-art tandem cold mills (TCM) according to the customer’s needs. Furthermore, the ZOOM (zero oriented off-gauge minimization) function developed by Steel Plantech can be added to improve yield ratios and reduce production costs as compared to conventional CRMs.

-

-

Tension Leveler

Tension levelers level and improve the flatness of materials such as hot rolled steel, cold rolled steel, stainless steel, aluminum, copper and specialized materials, and finish them into a final product. The range of the materials that can be used for leveling are those with a thickness of between 0.05mm-8.0mm, a width of between 300m-2,300mm and a yield strength of between 50MPa-1,500MPa. Tests of various materials using original testing equipment have been carried out on Steel Plantech’s tension levelers since 1970. Theories have been constructed, tested, and supply of tension levelers made, with this repeated many times over the years. 194 sets have been supplied around the world, practically making Steel Plantech a specialist in tension levelers.

-

-

Cold Mill (TCM,CRM)

Steel Plantech proposes a cutting-edge tandem cold mill (4Hi/6Hi) according to the customer’s needs. We can also provide total engineering, including auxiliary equipment such as utility facilities, inspection lines and roll shops.